Towards a Sustainable Future through a

Digital Product Passport

Designing sustainable products without compromising their benefits to human life.

CHALLENGE

Materials often lose value due to a lack of information about their composition and location within products. By giving materials an identity through a material passport, they retain value throughout their lifecycle. This involves creating a document that details all materials used in a product, facilitating their most effective re-use at the end of their life.

PROJECT OUTLINE

In today’s world, sustainable consumption is vital. Digital Product Passports (DPPs) empower consumers to make informed choices and help businesses demonstrate environmental responsibility. This project, created in collaboration with Nokia, explores how a DPP can enhance product lifecycle transparency and sustainability, showing how products can be fully recycled and value created from their materials.

RESULT

The project delivers a prototype Digital Product Passport, integrated into an app, showcasing complete product recyclability. The DPP allows owners to view products as material banks, enhancing the valuation and effective re-use of materials. By providing detailed information, the DPP supports sustainable design decisions and promotes a circular economy.

MEET THE DIGITAL PRODUCT PASSPORT

The Product Passport is a digital record providing comprehensive information about a product and its entire value chain. This includes details on the origin, materials used, environmental impact, and disposal recommendations. It clarifies how to reclaim materials, who is responsible for servicing, and all relevant information for stakeholders. The Product Passport closes the information loop in the supply chain, ensuring quality assurance and supporting circular economy principles.

Transparency for circularity

A material passport closes the information loop in the supply chain and ensures quality assurance. It prepares products and projects for integration into the circular economy. Material passports are valuable to various stakeholders: product manufacturers (understanding product composition and location), building/system owners and users (knowing what they own and its worth), disassembly companies (guidance on recycling and disassembly), and material suppliers (facilitating up-cycling).

Design for Sustainability

Products should be designed with sustainability in mind, considering both their current lifecycle and future recycling. Linked to a product passport via a QR code, products can be easily disassembled for recycling. Textiles are compostable, and technology components can be efficiently recycled by removing the plastic outer layer.

Sustainability for profitability

Designing products for recyclability creates sustainability that is also profitable. By optimizing assembly and recovery processes, companies can reuse materials and components, turning potential waste into valuable resources. This approach benefits the environment, reduces production costs, and demonstrates that sustainable practices can drive profitability.

EMBRACING NEW TECHNOLOGY

By embracing new technologies, the Nokia design team and I developed a novel method for producing electronic components that are protected and easily recyclable. Starting with flexible PCB technology, we created a way to encase the PCB in the same material, making it watertight, flexible, stretchable, and recyclable. Heating the plastic exposes the components, ready for reuse, combining protection with easy recyclability.

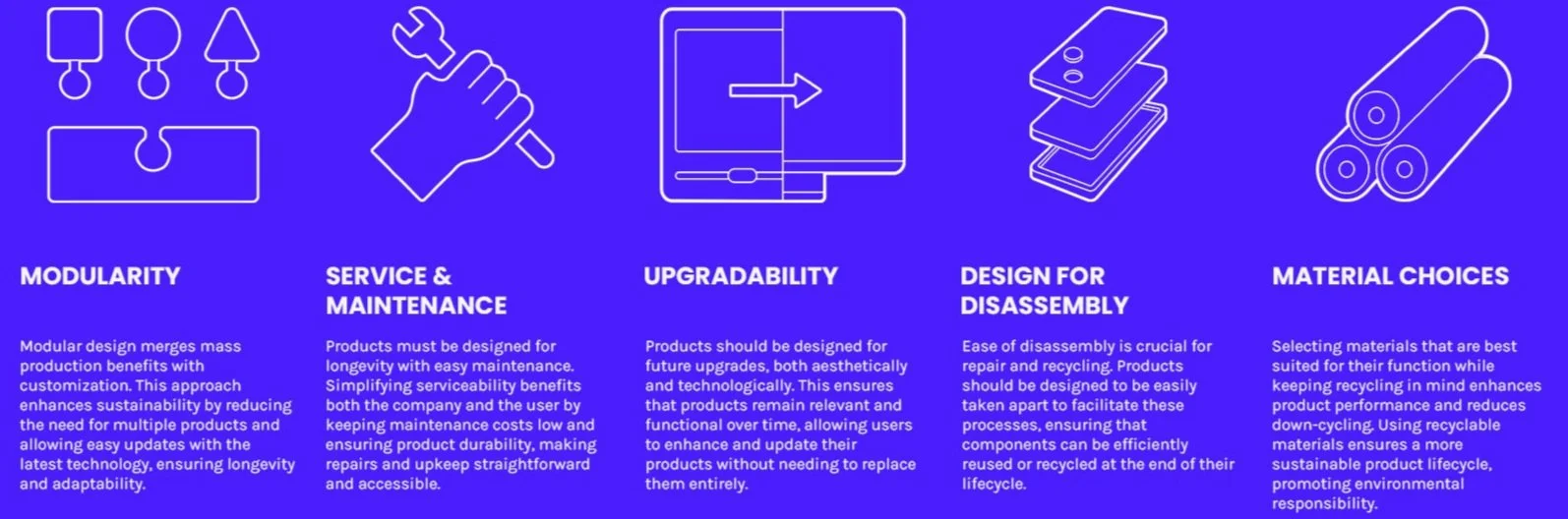

By looking beyond a product lifecycle for a single user we can change how products are made and recycled. It requires for us to design a bigger system, one that creates more value by enabling multiple usages and users of a product/material. If we wish for a product to be designed with sustainability in mind we should take the following five guidelines when developing a new product.